How to Correctly Apply a Metal Roof Paint in Corrugated Roofing

Coating with metal roof paint is one of the best methods in prolonging your roofing’s lifespan. However, applying paint on an elevated surface is not as straightforward as some people think. It requires proper method to properly do the job.

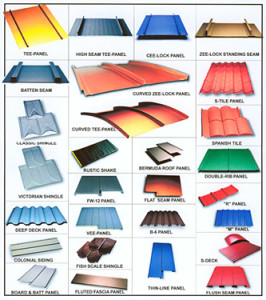

Metal roofs are becoming popular among homeowners because of their durability and fire-resistant quality. They also demand less maintenance than other types of roof materials. The biggest enemy of metal roofs is corrosion.

If you installed corrugated iron sheets on your roof, you will have to conduct regular repainting work to preserve the condition of the roof and extend its life. New metal roofs also require a paint job to protect them from the elements.

Primer and Degreaser

You have to wash a new roof with degreaser before applying a fresh coat of paint. Unpainted metal roofs that are a year or at least several months old may be painted on without the need to degrease them. New corrugated metal roofs contain oil on the surface from their fabrication, which could prevent paint from adhering to the surface. The oil is washed off from exposure to the weather.

You have to apply a primer first before painting any unpainted iron roof. New sheets placed after repairs must also be primed before coating is applied.

You can choose practically any paint color for your roof depending on your taste and overall design of the house. White is preferred by homeowners in hot places because it does not absorb heat from the sun. The general rule is you have to apply two coats of paint.

Airless Spry Gun

Using an airless spray gun is the fastest and most convenient way to paint a corrugated iron roof. Start from a predetermined area and spray about a meter wide portion and work your way down the sheet. You can use the joints on the sheets as your guide. After working down the sheet, go back up to the top of the roof and repeat the same for the next sheet.

Rollers

Specially-shaped rollers may also be used to paint a corrugated iron roof but you have to run down the brush on the joints because the rollers may not get into parts of the sheets that are raised.

Using Brush

If you want to use a brush, we suggest starting work early in the morning. Just work in small areas, about half a sheet at a time. Do not work during the hottest hours of the day because the heat will quickly dry the paint.